Why Need

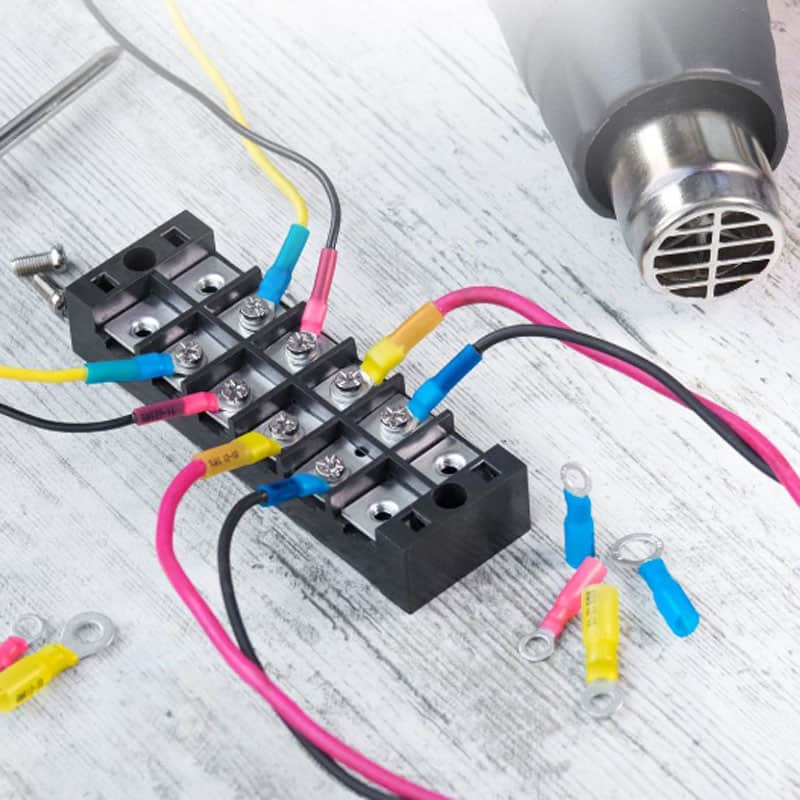

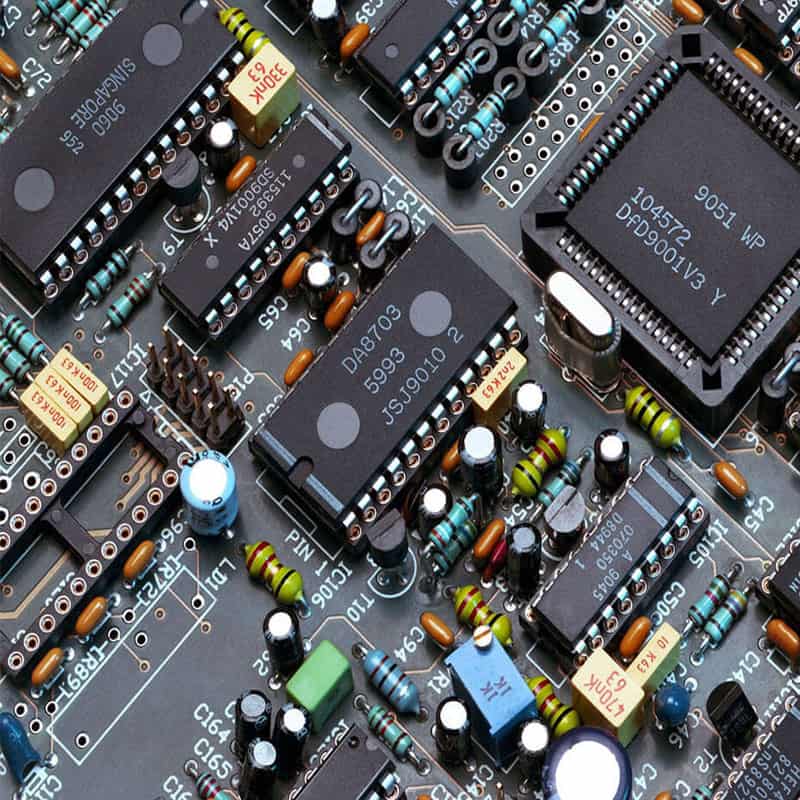

The electrical and semiconductor industry relies heavily on metal fabrication parts for durability, precision, and efficiency. These components are integral to ensuring the safe and reliable operation of electrical systems, ranging from infrastructure to consumer electronics.

Electrical systems demand components that can withstand high voltages, heat, and environmental conditions. Metal parts provide the robustness required for long-term performance. Electrical applications need parts with precise dimensions to ensure seamless integration and functionality. Metals like aluminum and copper are excellent conductors of heat and electricity, essential for many electrical components.

Solutions

- Custom Manufacturing: tailored parts to meet specific industry standards and project requirements.

- Material Expertise: use of specialized materials such as stainless steel, aluminum, and copper alloys for optimal performance.

- Advanced Processes: CNC machining, laser cutting, welding, and surface treatments to ensure high-quality finishes and accuracy.

- Scalability: capability to produce components in small batches or mass production to meet demand.

- Cost Efficiency: streamlined production processes reduce waste, saving time and costs without compromising quality.

Results

- Enhanced Reliability: Robust components reduce downtime and maintenance costs, improving system reliability.

- Improved Safety Standards: High-quality materials and designs minimize risks associated with electrical systems.

- Energy Efficiency: Conductive materials improve energy transmission, lowering energy loss and operational costs.

4. Sustainability: recyclable metal components contribute to eco-friendly practices and reduced environmental impact.

5. Innovation Enablement: custom solutions allow companies to adopt cutting-edge technologies in the electrical industry.