Why Choose Our Prefabricated Steel Structures?

Prefabricated steel structures are a modern solution to construction challenges, offering flexibility, durability, and efficiency. These structures are pre-engineered and manufactured off-site, then assembled on-site, reducing construction time and improving quality control. From commercial buildings to industrial facilities, prefabricated steel structures are transforming the way we approach construction.

- Faster Construction: With most of the construction completed off-site, these structures can be assembled quickly, reducing overall project timelines.

- Cost-Effective: The streamlined manufacturing and faster assembly process lead to lower labor and material costs, making prefabricated steel an economical choice.

- Durability: Steel is resistant to extreme weather conditions, pests, and rot, ensuring long-term stability and durability.

- Energy Efficiency: Prefabricated steel structures can be designed with energy-efficient materials and insulation systems, lowering operational costs over time.

- Sustainability: Steel is highly recyclable, making these structures an environmentally friendly option.

- Flexibility in Design: Steel structures can be customized to meet specific design needs, from aesthetic preferences to functional requirements.

Applications of Prefabricated Steel Structures

Commercial Buildings: Offices, retail stores, and shopping malls.

Industrial Facilities: Factories, warehouses, and manufacturing plants.

Agricultural Buildings: Barns, storage facilities, and greenhouses.

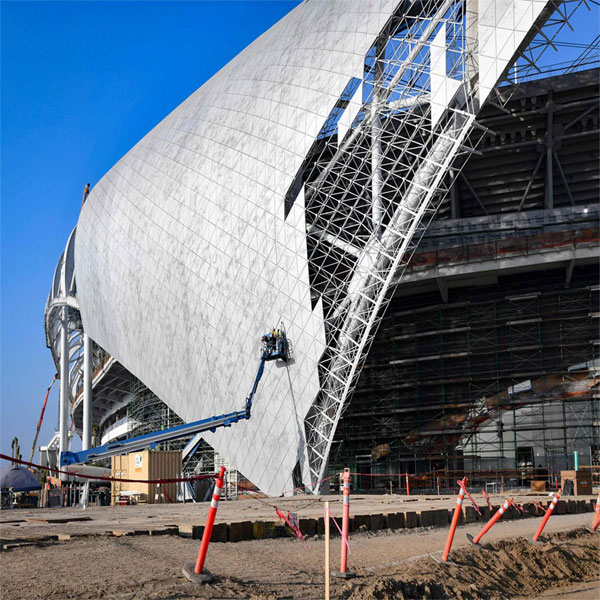

Sports Arenas and Halls: Large-scale structures for sports events and public gatherings.

Technical Comparison

When evaluating prefabricated steel structures, it is essential to understand how differences in quality can affect the performance, durability, and overall cost of the structure. Below is a technical comparison between bad quality and good quality prefabricated steel structures.

| Feature | Bad Quality | Good Quality |

| Material | Low-grade steel, weaker frame | High-strength, durable steel |

| Durability | Prone to corrosion, wear | Resistant to weather and corrosion |

| Precision | Poorly manufactured, misaligned | Precisely fabricated for easy assembly |

| Load-Bearing | Lower capacity, less stable | High load-bearing, more stable |

| Lifespan | Shorter lifespan, frequent repairs | Long-lasting, minimal maintenance |

| Cost | Lower initial cost, higher long-term cost | Higher initial cost, lower long-term cost |